Talent will decide how fast.

From simulated training suites in Cumbria to autonomous waste‑sorting lines at Oldbury, robotics is moving from promising pilot to day‑to‑day practice in UK nuclear decommissioning. The shift is tangible; Sellafield teams now train operators on a RAICo‑built Quadruped Familiarisation Tool (QFT) before they ever touch a robot, cutting risk, speeding readiness and protecting scarce kit. Early operator feedback reports improved confidence and competence, with the tool already deployed at Sellafield and Dounreay and being integrated into AWE training programmes.

Meanwhile, the Nuclear Decommissioning Authority (NDA) has launched Auto‑SAS, a four‑year, £9.5m programme to remotely and autonomously sort and segregate radioactive waste—first at the NRS Oldbury site. The goal is simple and high‑impact: classify waste more accurately so that lower‑risk items avoid costlier routes, while keeping people out of hazardous areas and upskilling the workforce that will operate, maintain and govern these systems.

Layer onto that the UK’s dedicated robotics research base, RAICo’s applied deployment mission in West Cumbria, and the National Centre for Nuclear Robotics (NCNR) consortium led by the University of Birmingham and it’s clear the UK has built a robust pipeline for translating research into field‑proven tools (from remote handling and size reduction to digital simulation and data‑driven inspection).

What’s new and why it matters for careers

1) Simulation and “train‑to‑proficiency” is now standard practice.

Quadruped robots (e.g., Spot) are increasingly used for inspections and dexterous tasks in areas unsafe for humans. But getting an operator fully confident can take days to weeks—time that ties up real robots and adds risk. The QFT changes that by giving photorealistic, site‑specific training environments and structured tutorials—so teams arrive on shift “mission ready,” and managers can track progress and tailor support.

Career signal: demand is rising for training programme owners, human‑factors leads, simulation product managers, and operations leaders who can integrate digital learning into the licence‑holder’s competency framework and safety case.

2) Autonomy is moving into high‑value waste operations.

The NDA’s Auto‑SAS programme will deploy multi‑sensor classification and robotic manipulation to route items to the correct waste stream, potentially saving hundreds of millions of pounds over time if scaled across the estate. It’s a whole‑system challenge: sensing, robotics, safety, cyber, data governance, logistics and regulatory engagement – all coordinated under rigorous programme controls.

Career signal: this creates immediate demand for systems engineers, safety case engineers, automation architects, OT cybersecurity leads, waste route specialists, and programme directors with experience orchestrating multi‑partner, multi‑site deployments within regulated environments.

3) The UK has a maturing R&D‑to‑deployment conveyor belt.

- RAICo (UKAEA, NDA, Sellafield Ltd, University of Manchester, AWE) exists to accelerate robotics and AI deployment for fission decommissioning and future fusion operations, with a hands‑on facility (RAICo1) in Whitehaven for realistic testing (gloveboxes, tanks, hot‑cell analogues) and an expanding programme aligned to end‑user needs.

- NCNR has delivered 400+ peer‑reviewed papers, world‑firsts such as AI‑controlled robot arms in radioactive environments and autonomous drone deployments at Chernobyl and Fukushima and has trained 60+ early‑career researchers – a pipeline the sector can now absorb into delivery.

Career signal: with capability maturing, the binding constraint is shifting from “tech feasibility” to “delivery at scale”—i.e., programme leadership, commercial and supply‑chain integration, and sustained operational management on licensed sites.

4) The skills narrative has moved from “cool robots” to “safer, faster, cheaper—and business as usual.”

NDA leadership underscores that having “the right skills in place” is key to accelerating deployment, and that robotics provides opportunities to remove people from harm while developing new skills across the workforce. These aren’t pilots for curiosity’s sake; they are mission‑aligned tools for a century‑scale clean‑up and a material part of the UK’s value‑for‑money mandate.

The mid‑career to executive gap: why nuclear needs you now

Is there demand for mid‑career to executive engineering and project‑delivery professionals? All signs point to yes and growing.

- Programmatic scale and complexity: Auto‑SAS alone is a multi‑year, multi‑partner transformation that must pass through inactive to active demonstrations, then replicate to other NDA sites, classic territory for seasoned programme directors, PMOs, and contract managers who can hold cost/schedule, risk and benefits realisation across regulated boundaries.

- Operational integration: RAICo’s mission is end‑user deployment, not lab demos. That means site integration leads, configuration/asset managers, site acceptance authorities, and operations leaders who can carry upgrades into plant and sustain them under ALARP, security and information governance constraints.

- Safety case and regulatory engagement: moving from trials to “business as usual” requires leaders who can translate novel RAI systems into the safety case, oversee HAZOP/LOPA and HFE integration, and shape pragmatic operating envelopes with the regulator. (NCNR’s high‑TRL demonstrations show the technical side is ready; now comes the leadership to institutionalise it.)

- People and capability building: the sector is explicitly investing in upskilling and new training pathways, from RAICo’s simulation work to workforce development embedded in the NDA programmes demanding heads of training, capability & competency managers, and change leaders to embed new practices at scale.

Put simply, technology is no longer the bottleneck. Leadership, integration and delivery capacity are. For mid‑career engineers and project professionals with experience in systems integration, industrial automation, safety‑related software/firmware, or large capital projects this is a rare moment to step into roles where your judgement and delivery discipline will compound technology benefits across an entire estate.

Five role archetypes the NDA estate and supply chain need more of (now)

- Head of Robotic Operations (Site/Cluster) – Owns deployment roadmaps, availability/reliability, configuration control and continuous improvement of robotic platforms across facilities; accountable for training currency, emergency response interfaces and cyber‑OT posture.

- Programme Director, Autonomous Waste Systems – Runs end‑to‑end delivery (requirements → inactive → active), integrates supplier ecosystem (e.g., ARCTEC), and leads benefits tracking for waste route optimisation and dose reduction across multiple sites.

- Principal Systems Engineer (RAI) – Leads V‑model/MBSE for sensing, manipulation, teleoperation and autonomy; ensures safety‑class segregation, SIL allocation, and test/verification traceability into the safety case.

- Operations & Training Transformation Lead – Builds simulation‑first training, certifies operator competence, and embeds human‑factors learnings from digital twins into SOPs and emergency procedures.

- Strategic Partnerships & Supply‑Chain Lead (Robotics) – Orchestrates academia–industry–site collaborations (RAICo/NCNR, SMEs, primes), structures IP and data‑sharing, and scales proven tech across the estate with consistent commercial and governance frameworks.

How professionals can pivot in (or up) fast

- Anchor your story to safety, schedule, and value. Frame automation outcomes in terms of dose reduction, access to hazardous zones, cycle time and costed benefits – the language of regulators and CFOs alike. The Auto‑SAS case is a clear exemplar.

- Show that you can industrialise prototypes. Point to times you’ve moved tech from demo to “business as usual” with change control, training, spares, and governance – exactly what RAICo and site teams need now.

- Invest in your RAI literacy (fast). If you’re a delivery leader, spend time with quadruped ops, teleoperation/HMI, and digital simulation methods that the QFT embodies so you can challenge, sponsor and unblock effectively.

- Engage the UK network. The UK has a unique collaboration fabric (RAICo hubs; NCNR universities; site‑owner forums). Plugging in accelerates onboarding and exposes you to live challenges seeking owners.

The bottom line for nuclear‑careers.com readers

Robotics and AI are now core enablers of the NDA mission, not experimental side projects. The technology stack, from simulation‑led training to autonomous waste sorting, exists and is being fielded. What will govern the slope of the adoption curve is talent; people who can lead, integrate, assure safety, and deliver at pace in complex, regulated environments. If you are a mid‑career to executive‑level professional in engineering, operations, safety or programme delivery, this is your moment to have outsized impact on a national clean‑up that will last generations.

Sources

- Nuclear Engineering International (Jan 21, 2026) – “Accelerating robotic deployment” (RAICo’s Quadruped Familiarisation Tool and operator training insights).

- GOV.UK (June 26, 2025) – “NDA launches pioneering robotics partnership to manage nuclear waste” (Auto‑SAS scope, funding, timeline, skills/upskilling emphasis).

- RAICo (raico.org) – Collaboration mission, technology themes, and deployment focus (RAICo1, end‑user integration).

- University of Birmingham – NCNR – National Centre for Nuclear Robotics outcomes: world‑first deployments, training and high‑TRL demonstrations.

- NDA Blog (2016) – “The role of robotics in nuclear decommissioning” (principles, benefits and early case studies underpinning today’s deployment mindset).

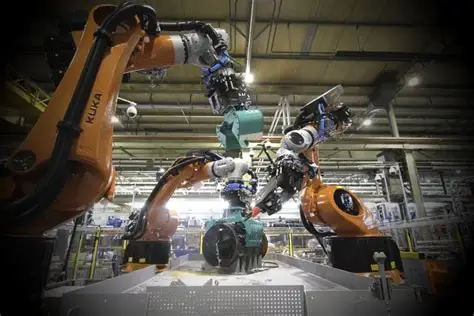

Picture: Sellafield & NDA Group