One year into the latest U.S. administration, the energy sector has experienced tectonic policy shifts that blend industrial urgency with geopolitical ambition.

At the centre of these changes is a refocusing of national energy strategy toward speed, security, and domestic competitiveness, changes already influencing the workforce demands across clean, reliable baseload technologies such as nuclear.

Digital Infrastructure Drives a New Era of Energy Demand

A surge in U.S. data‑centre expansion, treated as a strategic national asset, has been one of the clearest signals of this new policy direction.

With digital infrastructure now dictating energy priorities, the emphasis on grid reliability and uninterrupted power supply has intensified.

For the nuclear sector, long valued for its stability and low‑carbon generation, this creates a renewed platform to position reactor technologies and nuclear‑skilled professionals as essential to the digital economy’s energy backbone.

Tariffs and Supply Chain Disruption Shift Skills Requirements

A sweeping escalation in tariffs has strained supply chains for core energy‑sector materials, from metals to power‑system components, raising project costs and injecting uncertainty across the industry.

The ripple effect has already driven a dramatic rise in tariff‑related job postings, signalling the need for specialists who can navigate complex procurement, regulatory, and engineering challenges.

For nuclear employers, this environment increases demand for professionals skilled in supply‑chain resilience, component qualification, and strategic sourcing.

Persistent Demand Growth Strengthens the Case for Nuclear Talent

Despite volatility, U.S. power demand continues to surge at record levels. Utilities and developers are being pushed to innovate, diversify, and accelerate project pipelines.

Because nuclear offers round‑the‑clock reliability, predictable generation, and enhanced energy security, these conditions heighten the sector’s strategic relevance and intensify the need for a workforce capable of delivering new build, life‑extension, SMR deployment, and advanced reactor innovation.

What This Means for the Nuclear Workforce

The evolving U.S. landscape underscores a global truth; energy security, digital growth, and clean power commitments are converging, and nuclear expertise sits at that intersection.

For organisations and professionals in the nuclear industry, this moment calls for:

- Adaptive skills in regulatory policy, geopolitically aware supply‑chain planning, and safety‑critical engineering.

- Strategic leadership capable of guiding complex capital projects through shifting market and policy conditions.

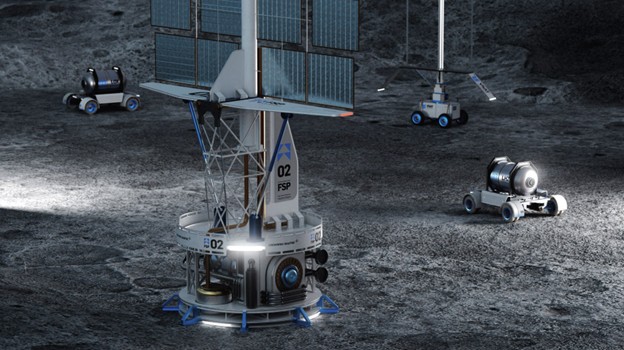

- Innovation‑ready talent prepared to support SMRs, microreactors, advanced fuels, and hybrid energy systems.

- Cross‑sector fluency, especially with digital infrastructure, storage, AI‑driven grid optimisation, and industrial decarbonisation.

As the energy landscape transforms, nuclear careers are not just participating, they’re becoming central to enabling resilient, future‑proof power systems.

Picture: businessinsider.com