Last Energy Secures Oversubscribed $100M Series C to Accelerate Microreactor Commercialisation.

Last Energy, a fast‑growing developer of modular micro‑nuclear reactors, closed an oversubscribed Series C round in December 2025 exceeding $100 million, marking one of the most significant recent investments in next‑generation nuclear deployment. The round was led by the Astera Institute with participation from JAM Fund, Gigafund, The Haskell Company, AE Ventures, Ultranative, Galaxy Interactive, and Woori Technology Co., Ltd.

This new capital positions the company to fully fund its U.S. DOE pilot reactor, accelerate commercialisation of its PWR‑20 microreactor, and expand its U.S. manufacturing footprint, demonstrating growing investor confidence in factory‑built nuclear solutions. A Major Milestone for the Microreactor Market

Last Energy describes this raise as transformative for its transition from demonstration to commercial power plant deployment. According to CEO Bret Kugelmass, the funding will support their DOE pilot and help prove out “how factory fabrication will unlock the scalability that the energy market demands.”

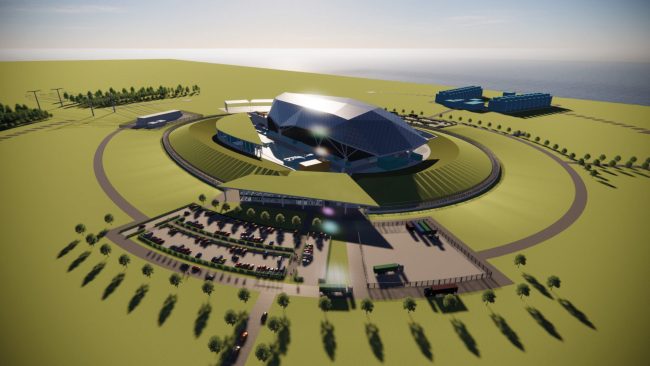

For an industry increasingly focused on energy security, electrification of heavy industry, and clean baseload power, Last Energy’s modular approach, centred on 5–20 MWe reactors, offers a scalable nuclear product designed for real‑world, near‑term deployment.

Advancing the PWR‑5 Pilot and Commercial PWR‑20 Reactor

Following the Series C round, Last Energy is prioritizing three major initiatives:

1. Completing the PWR‑5 Pilot Reactor: The PWR‑5, a 5 MWe demonstration reactor physically identical to the commercial PWR‑20 but scaled down, will serve as the proving ground for Last Energy’s factory‑fabricated approach.

2. Accelerating PWR‑20 Commercialisation: The PWR‑20 is the company’s flagship 20 MWe microreactor designed for industrial off takers such as data centres, manufacturing facilities, and ports.

3. Expanding Manufacturing Capacity in Texas: The new funding allows Last Energy to strengthen its Texas manufacturing footprint and deepen local partnerships to support serial production.

Regulatory Progress in the U.S. and UK

United States: DOE Pilot and First‑of‑its‑Kind Agreements

In August 2025, Last Energy was selected for the U.S. DOE’s Reactor Pilot Program, secured a long‑term lease at the Texas A&M–RELLIS campus, and signed the first known Other Transaction Agreement (OTA) between DOE and a reactor developer. This positions the company for an anticipated 2026 criticality demonstration.

United Kingdom: Leading the Race for Microreactor Licensing

Last Energy is also the only company with a regulator‑confirmed pathway toward a potential 2027 UK site license decision, having completed its Preliminary Design Review (PDR) with the ONR, Environment Agency, and NRW.

Its recognition by the Atlantic Partnership for Advanced Nuclear Energy further underscores the UK’s support for U.S.–UK collaboration on small reactor deployment.

Investor Confidence in Next‑Gen Nuclear

Investors highlighted the transformative nature of Last Energy’s productised, modular approach:

- Astera Institute emphasised the company’s “ambitious” product mindset and transformative potential for power generation.

- Galaxy Interactive pointed to the essential role of clean, reliable power for enabling industrial and economic growth, calling Last Energy’s model one of the “most capital‑efficient” approaches in the nuclear space.

Key Insights for the Nuclear Sector

Microreactor investment momentum continues to accelerate as private capital seeks scalable clean‑energy solutions.

Last Energy’s factory‑built PWR‑20 microreactor is positioned as a leading candidate for rapid industrial deployment.

Strong progress along both U.S. and UK regulatory pathways makes Last Energy one of the most advanced microreactor developers globally.

The company’s expansion into Texas manufacturing highlights growing demand for domestic nuclear supply chain capacity.

A Defining Moment for Microreactor Commercialisation

Last Energy’s oversubscribed $100M Series C underscores the growing confidence in modular nuclear reactors as essential infrastructure for the next generation of clean energy systems. With regulatory traction, industrial partnerships, and new capital in hand, the company is now positioned to deliver commercial microreactors in the second half of the decade, an inflection point for the global nuclear workforce and supply chain.

Picture: Last Energy